![]()

Focus on Industrial Utility Efficiency

The mission of Blower & Vacuum Best Practices is to help Energy Managers create Industrial Energy Savings while maintaining and often improving the reliability of the process. We focus only on projects with ROI’s in the 0-3 year range.

Blower System and Blow-off Optimization

Industrial blower applications, aeration blowers and blow-off air opportunities are the editorial focus on the blower side.

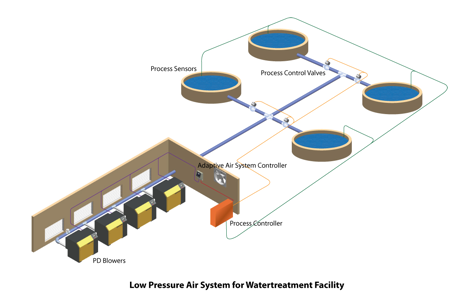

For example, blowers support aeration systems at industrial and municipal wastewater treatment facilities and represent a significant portion of the over-all energy consumption. According to Jess Burgess from the Consortium for Energy Efficiency, “Aeration accounts for 25-60 percent of total energy consumption at typical wastewater treatment facilities.” Aeration is often the largest single energy-user in a municipality. Optimizing the blowers and blower controls of the aeration system has been proven to be a huge opportunity with excellent ROI’s. Matthew Gray from BioChem Technology stated, “The implementation of a properly designed aeration control system has been reported by the United Sates Environmental Protection Agency to reduce aeration energy by 25 to 40 percent.”

Vacuum System and Vacuum Generation Optimization

|

|

|

The Becker water separation system for the dry pumps at the calibrator at MGM Industries |

Industrial rough and medium-vacuum system optimization, as well as vacuum-generation optimization are the editorial focus on the vacuum side.

Industrial vacuum audits will examine a range of areas including the vacuum specification. Expert auditor Jesse Krivolavek, from IVS, Inc. said, “Sometimes, we see operators cranking the vacuum as deep as possible, usually fearful of operating anywhere less than “their standard”. We’ll see plants with a central vacuum systems operating at 24”Hgv at the furthest machine (26”Hgv at the pumps), when they only needed 18”Hgv (or 20”Hgv at the pumps). The energy consumed to create about 4”Hg-absolute (26”Hgv), when they could be creating 10”Hg-absolute (20”Hgv), is more than twice as much necessary. The potential energy saving can be a big deal.”

Vacuum system audits can also yield unexpected benefits. A case study at a plastics extruder details how Becker replaced liquid ring vacuum pumps with a dry rotary vane vacuum pumps equipped with special-engineered water separation systems. The factory, MGM Industries, was able to significantly reduce their chilled water consumption and avoid purchasing a new 100-ton, $120,000 chiller!

Our Team

|

Roderick Smith is the Co-Publisher of Blower & Vacuum Best Practices Magazine. Mr. Smith worked as an executive in the compressed air industry from 1992 to 2006. Seven of those years were spent developing business in Spain and Germany. Mr. Smith serves as the Editor and Sales Manager of Blower & Vacuum Best Practices Magazine. |

|

Patricia Smith is the Co-Publisher of Blower & Vacuum Best Practices Magazine. Mrs. Smith is responsible for the Operations, Online Products and General Administration of Smith Onandia Communications LLC. |

|

Anna Buzzelli serves as the graphic designer of Compressed Air Best Practices magazine®, Chiller & Cooling Best Practices Magazine, and Blower & Vacuum Best Practices Magazine. She has been designing for the publication and formatting the magazine since its inception. |

|

Clare Heinl serves as the Circulation Manager of Blower & Vacuum Best Practices Magazine. She has a Masters Degree in Sustainability and is Google Analytics certified. |

|

Mike Grennier is a Contributing Editor to Blower & Vacuum Best Practices Magazine. He brings extensive experience as a technical writer familiar with rotating equipment and cooling systems. |

|

Kimberly Hill serves as the Sustainability Events & Operations Manager for Blower & Vacuum Best Practices Magazine. She has a Bachelor’s Degree in Environmental Science as well as a Master of Business Administration. |

|

Bill Smith serves as a Associate Content Manager for Blower & Vacuum Best Practices Magazine. He has Bachelor’s Degrees in Digital & Print Journalism, and Spanish. |

|

Patty Mackey serves as Circulation Specialist for Blower & Vacuum Best Practices Magazine and Events Coordinator. She has a Bachelor’s Degree in Finance.

|

Roderick Smith - Publisher

Roderick Smith - Publisher Patricia Smith - Publisher

Patricia Smith - Publisher Anna Buzzelli - Graphic Designer

Anna Buzzelli - Graphic Designer Clare Heinl - Circulation & Events Assistant Manager

Clare Heinl - Circulation & Events Assistant Manager Mike Grennier - Contributing Editor

Mike Grennier - Contributing Editor Kimberly Hill - Sustainability Events & Operations Manager

Kimberly Hill - Sustainability Events & Operations Manager Bill Smith - Digital Content Specialist

Bill Smith - Digital Content Specialist Patty Mackey - Circulation & Events Assistant Manager

Patty Mackey - Circulation & Events Assistant Manager