By Andrew Balberg, Lone Star Blower, Inc.

03/23/2020

Great news! The American Society of Mechanical Engineers (ASME), which is a world renowned and recognized standards organization, has released ASME PTC 13, Blowers; a new power test code providing complete technology neutral performance test specifications for blowers. Here are some of the reasons behind the creation of PTC 13 and how it benefits all.

Having been in the blower industry for quite some time I was always a bit frustrated by the lack of ability to definitively prove blower package performance and energy efficiencies; or even disprove some outrageous claims made in the market. It seemed anyone with a glossy brochure could claim the best efficiency.

Additionally, plant owners and consultants have numerous blower technology options to evaluate, but uniform evaluations of efficiencies between blower technologies were neither readily available nor encompassed by any third-party specifications. Further, there was no consideration of the entire packaged system with regard to its overall energy use.

These issues led to misinformation and unrealistic representations of different blower technologies. It took an extended effort by any individual to obtain correct information to make an accurate and educated decision on which technology was the best fit for their application. With PTC 13, however, the end user can now get an accurate estimate and proper verification of how much wire power is consumed for the delivered air to their process; plus, they now have the ability to compare all blower technologies on a level playing field.

Formation of ASME PTC 13 Committee

In 2008, ASME was solicited as a venue to address these issues and develop a new code as it was important to have a third-party international standards organization sponsor. It was also important to have this code written by the users of these codes rather than a specification offered or directed by the manufacturers; thus, the PTC 13 Committee was largely driven by engineering consultants in the water and wastewater industry. These consultants represent the majority of members to keep the end user point of view as the focus of the test code.

The committee also wanted the test code to be easily verifiable through witness testing by personnel who may not be experts in rotating equipment or testing procedures. Doing so makes the code as transparent as possible to the end users.

When founding the committee, little did we know it would take 10 years and many, many hours of dedication from the committee to achieve this objective. I want to congratulate the founding members listed below and acknowledge all committee members, past and present. This process required hundreds of unpaid hours for committee members to invest in this cause and this code could not have happened without them.

Lloyd Slezak - Brown and Caldwell

Hiran del Mel – Jacobs

Julia Gass - Black & Veatch

Tom Jenkins - JenTech, Inc.

Jacque Shultz- Howden North America, Inc.

Ralf Weiser, Aerzen USA

Andrew Balberg – Lone Star Blower/GL-TURBO

ASME PTC 13: An Industry First

ASME PTC 13 is the first power test code used in the measurement of electric power consumption of packaged air blowers that covers all blower technologies in a complete “wire to air” approach.

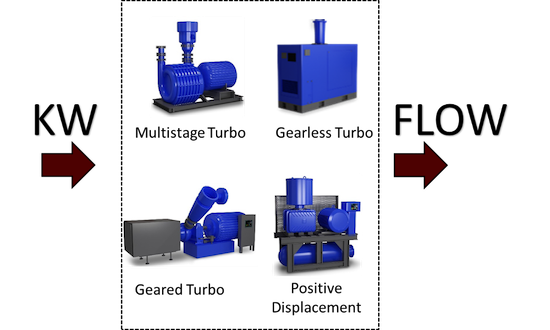

ASME PTC 13 provides a test for measuring electrical power consumption of all blower technologies.

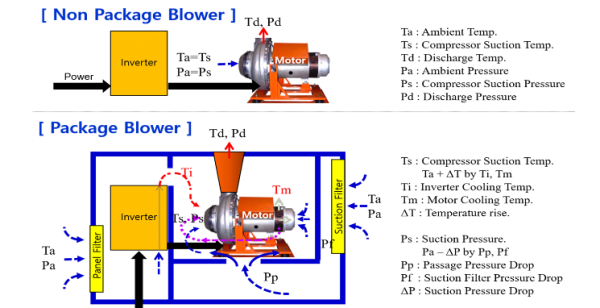

The wire-to-air approach encompasses the total electric power consumption required to produce a specified flow and pressure delivery from any blower technology. It is measured at the power input to the blower package and includes all power-consuming electrical components of the blower package as required for installation and normal operation, including inlet and discharge accessories, the drive motor, Variable Frequency Drive, cooling system, controllers etc.

Shown are the differences between a non-packaged and packaged blower.

No such code existed previously in the market for packaged power that was applicable and fair to all technologies. In other words, the question of how much power comes from the wall and how much flow comes out of the entire blower system is finally answered. All losses in between are accounted for in the code.

Which Blower Technology is Best?

Energy savings in municipal wastewater projects are a paramount factor in evaluating different technologies. Thus, the question is often asked, “Which blower technology is the most efficient?” The short answer is, “It depends.”

Sorry to disappoint without a definitive answer. While the PTC 13 specification can be uniformly applied to all blower technologies in a fair and unbiased way, it is your process and the range of operation that will give you this answer. In general, you can say centrifugal/turbo type technologies can achieve much higher efficiencies versus positive displacement/screw types due to not having the same speed limitation; but more importantly, your process and range of operation will best answer this question.

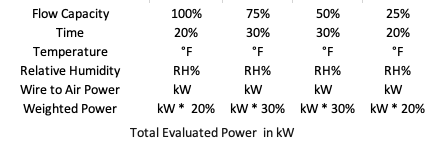

Using an Evaluated Power Table across of range of expected operation conditions, such as the example shown in the following table, can provide a better indication on performance and illustrate which technology would perform best for your application.

When in doubt ask the question, “At this range of flow and pressure needed for my particular process, what is the input power, without any negative tolerance, for the complete blower package using the new PTC 13 code?” The answer or solution with this code will help in answering the bigger question of, “Which blower technology is right for my application?”

Here is a link to the ASME website to get your copy of the PTC 13 Code: https://www.asme.org.

About the Author

Andrew Balberg has been in the blower industry since 1997 as a manufacturer/owner and has overseen nearly 5,000 blowers tested and sold in the market. He solicited and received approval from ASME to form the committee to write the PTC 13 code, offering the industry a true wire-to-air standard. Balberg is Founder and President of Lone Star Blower/GL-TURBO HOUSTON, tel: 832-532-3112, email: abalberg@lonestarblower.com.

About Lone Star Blower, Inc.

Lone Star Blower, Inc. is a manufacturer and service company for blower and blower control systems located in Houston, Texas. Products range from 20 to 6,000 horsepower (hp) and up to 90,000 cfm. Technologies include gear driven single stage geared turbo blowers, high-speed gearless turbo blowers, and vertically split multistage turbo blower technologies. We serve the industries of water and wastewater, power, petrochemical, oil and gas, food and beverage, mining, and many others using compressed air or gas in pressure or vacuum applications. Lone Star is part of GL-TURBO global network of companies. For more information, visit www.lonestarblower.com.

All photos courtesy of Lone Star Blower.

To read similar aeration blower standards articles, visit www.blowervacuumbestpractices.com/standards/blower-standards.