The objective of this article is to look at typical industrial wastewater agitation processes and share various energy saving compressed air/blower projects that have worked well over the years. These basic fundamentals are a good starting point to begin the evaluation of a project idea.

There are three primary uses of compressed air in all wastewater treatment applications. This article will focus on agitation and movement of materials.

- Aeration to supply the processing bacteria with oxygen support

- Agitation to keep the solids in suspension and,

- A continuous, driving pump to move the material.

Wastewater Municipal Water & Sewage Treatment

- Compressed air used for agitation to keep solids in suspension

- Compressed air is often needed to supply oxygen support to the processing bacteria

Air pressure required depends on

- Liquid/slurry depth

- Actual water head pressure 2.31 feet equals 1 psig

- For estimating we use .5 psig per foot of head of H2O -- specific gravity of water is 1.0. Mixtures and slurries with higher specific gravity will have greater head pressure

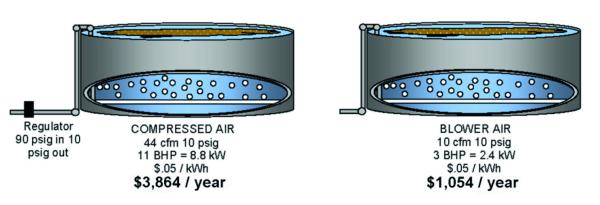

Will Pressure Requirements Allow the Use of a Blower?

The lower the required pressure, the lower the energy cost, per scfm of delivered volume of compressed air, with the same type and class of compressed air (or blower) operating equipment. This is generally true regardless of the type of compressed air generating unit as long as the pressure flow is within a given machines’ operating parameters.

This sounds somewhat simple – just identify the minimum acceptable pressure that works and the required or current actual compressed air flow being used. Then, select the appropriate blower or air compressor. In an existing plant or operation this can often be challenging since many operators do not have nor know this information.

|

Typical Operating Cost for 500 cfm at Various Pressures |

||

|

Electrical Energy Cost |

500 cfm at 100 psig |

\$43,000 |

|

500 cfm at 50 psig |

\$26,000 |

|

|

500 cfm at 15 psig |

\$18,000 |

|

|

500 cfm at 7 psig |

\$8,000 |

|

|

500 cfm at 4 psig |

\$5,000 |

|

In the field you can measure the flow and inlet pressure, but to accurately estimate the probable lowest usable discharge pressure you will need to know the specific gravity of the solution and the overall height of the liquid or slurry material (depth) to establish the “head pressure” to be overcome.

Unlike a municipal sanitary sewer wastewater treatment facility this data is often not only not readily available but also may well vary over time and application in the industrial wastewater environment.

Generally compressed air is combined with some type of liquid or slurry pump appropriate to handle the material. Often this is an air operated double diaphragm (AODD) pump due to its simple design and versatile application parameters. They are also relatively quick to repair and/or change. Electric driven pumps are often not even considered.

Basic Methods of Aeration / Agitation

When aeration is required for the oxygen supply then the choices (outside of blowers) are somewhat limited. If forced to use 100 psig compressed air, the economic opportunities are:

- Investigate the savings if an electric pump can replace the air driven pump. The primary limiting factors to economic use of an electric in lieu of air driven is the head pressure required (viscosity and depth) and make up of the material.

- If an air operated double diaphragm pump (AODD) is the proper selection, identify the lowest effective inlet pressure and add an electronic stroke optimizer. These controls can reduce the air use 40 to 50%, delivering the same throughput while incorporating automatic starts/stop if applicable.

- Identify the proper pressure and flow to select the most effective compressed air supply (a blower) as described earlier.

Agitation

When compressed air is used (with or without a process pump) primarily for agitation, additional opportunities exist to deliver the same agitation results at a lower energy cost. Even though compressed air power is very expensive, these other actions should always be carefully evaluated on specific case by case conditions to establish an accurate operation energy cost.

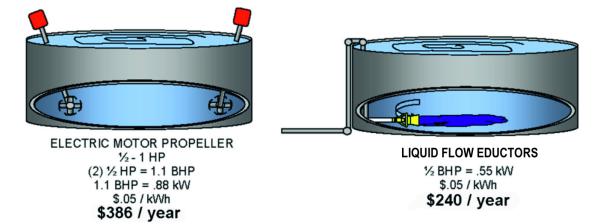

Liquid Flow Eductors Replace Agitation Air at a Refinery

The principle of operation of a Liquid Flow Eductor is that liquid is pumped into the eductor nozzles and exits at high velocity, drawing an additional flow of the surrounding solution through the educator. This additional flow (induced liquid) mixes with the pumped solution and multiplies its volume five-fold. The source of the pumped liquid (input) can be a pump or filter chamber discharge.

Eductor agitation delivers five times the pump output at each nozzle. This effectively helps deliver the required level of agitation to critical areas. When appropriate and properly engineered and installed, this can often supply proper agitation at lower energy input.

At a refinery, the caustic production utilized two 40’ tall tanks with 15’ depth. Measured air flow was 240 scfm to both wastewater holding tanks. The air was delivered through three 3/4" lines on three sides of the holding tank. The blowing air was able to keep the solids off the inside walls. There was also a 20 horsepower pump that continually circulates the mixture to keep the solids off the bottom and in suspension.

| Estimated Energy Use | |

| 240 scfm at estimated 4 scfm per input hp at 100 psig | 60-hp |

| Electric motor driven pump | 20-hp |

| Total energy | 80-hp (66.3 kW) |

| Estimated annual current electrical energy cost | \$34,847/yr |

| (80 x .746 ÷ .90 @ \$.06 kWh / 8,760 hrs/yr) |

The project implemented consisted of installing three eductor patterns at appropriate points on the tank walls and a double set on the bottom. The new eductor system held the solids in suspension as required allowing appropriate storage time between cleaning and clearing. The total energy input requirements, of the liquid flow eductors, consisted of the use of a 10 horsepower (8 kW) duplex centrifugal pump.

| New Energy Use | 8 kW |

| Total electric power operational savings (kW) | 58.3 kW |

| Estimated annual total electric energy savings (\$.06 kWh / 8,760 hrs/yr) | \$30,642 |

| Total project cost (with installation) | \$20,000 |

| Simple payback | 7.8 months |

Filter Press at a Steel Processing Plant

A filter press, at a steel processing plant, was running an air operated double diaphragm pump (AODD) during a complete four-hour cycle. The filter press would run for a four-hour cycle with a 30 minute final press requiring 150 feet of head pressure at the end of each cycle. Prior to the final press, head pressure is 30 to 40 feet for 3.5 hours per cycle.

The project was to install a 2-hp electric motor driven centrifugal water pump to complement the AODD to operate the press the first 3.5 hours of the 4-hour cycle. The AODD will now run the last half hour of each cycle. The production process runs 24 hours a day, 7 days a week, 365 days a year with a blended power rate of $.10 kWh.

| Current air flow to 2” AODD | 80 scfm |

| 80 scfm at 90 psig at estimated input power (20 hp x .746 ÷ .90) | 16.6 kW |

| Estimated annual electrical energy cost (16.6 kW x \$.10 kWh x 8,760) | \$14,542/yr |

| Modified Operation | |

| AODD: 16.6 kW x 12.5% (1,095 hours out of 8,760) x $.10 kWh | \$1,817.70/yr |

| Centrifugal pump: 1.7 kW (2-hp motor) x 7,665 hrs/yr x $.10 kWh | \$1,303.05/yr |

| Total estimated annual operating air | \$3,120.75/yr |

| Total annual savings | \$11,421.25/yr |

| Total project cost | \$5,000 |

| Simple payback | 5.3 months |

Agitation Project at a Chlorine Plant

A chlorine plant had two 40 foot tall wastewater final stage polishing tanks used to treat the wastewater before releasing to groundwater (fluid depth 30 feet). The application used 220 scfm of compressed air at 90 psig, which was regulated down to 15 psig to supply agitation to maintain clarity. The air was delivered to the bottom of each tank from which it bubbled up through the water.

| Estimated electric power to produce the 220 scfm at 4 cfm per input hp | 55 hp |

| Estimated electric power x .746 ÷ 90 | 45.6 kW |

| Operating cost (8,760 hrs @ \$.10 kWh) | \$39,945/yr |

The first alternate technology considered was utilizing the “liquid flow eductors”. However, the power to handle this tall and wide tank was 75 hp (62 kW) which was obviously not a calculated savings so the idea was abandoned.

Supplying the low-pressure air at 16 psig with a single-stage helical lobe blower was next explored.

A helical lobe blower using a 25 hp electric motor with 22 bhp power draw (22 x .746 ÷ 90 - or 18.2 input kW) will deliver 239 scfm at 15 psig. With this, the primary estimated annual energy cost is \$15,944/yr (18.2 x \$.10/kWh x 8,760 hrs) or an annual electrical energy savings of \$24,000/yr. The installed cost of the new blower package and piping was \$14,000 (up to \$28,000 depending on the package). This provided an anticipated simple payback of 7 to 12 months.

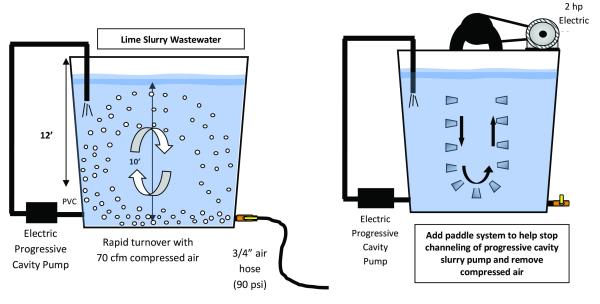

Steel Mill Wastewater Agitation Project

The last case study example is in a steel mill’s wastewater treatment area where the limestone slurry tank is agitated with a 30 hp progressive Moyno cavity pump in a 12 foot tall by 8 foot diameter tank. The lime must be effectively kept in suspension to avoid channeling with solids buildup around the pump entry blocking effective agitation.

The solids can block the recirculation volume, which accelerates the fouling factor and significantly increases the number of expensive cleanings. This can be a significant environmental and time-consuming issue to clean out. This situation is in all probability also affecting production.

The goal was to keep the solids in suspension until the regular scheduled maintenance time. Premature fouling was currently avoided by adjusting fluid tank levels as required when maintenance personnel found time. This situation was not only troublesome but could lead to unplanned significant downtime with the current manpower situation.

After the tank was cleared of solids and reset to avoid a reoccurrence, a 3/4" air line at 90 psig entry pressure was opened into the bottom side of the tank. The measured flow was 80 scfm, it did do the job.

| Total estimated pump power (30-hp [x .746 ÷ 90]) | 24.9 kW |

| Total air flow 80 scfm (80 ÷ 4 sec/input hp = 20-hp x .746 + .9) | 16.6 kW |

| Total estimated power utilized (8,760 operating hours/yr @ \$.10/kWh) | 41.5 kW |

| Total current estimated electrical operating energy cost | \$36,354/yr |

A mechanical mixing assist with paddles was added to replace the 1” air line (see drawing). This arrangement was driven by a 2-hp electric motor (2-hp x .746 ÷ .85) or 1.75 kW. This has proven to be very successful.

| New configuration electrical operating energy: | |

| - 0-hp progressive cavity pump | 24.9 kW |

| - Mechanical paddle pump | 1.75 kW |

| Total electrical operating energy power | 26.65 kW |

| Total electrical operating annual energy cost | \$23,345/yr |

| Total electrical energy savings | \$13,009/yr |

| Cost of project | \$2,540 |

| Simple payback | 2.3 months |

Summary

If air is needed for the wastewater treatment process and agitation alone is not enough, then there are really two choices – blower air or air compressor air. The proper choice will have a very positive impact on energy costs and correctly applied and maintained, should enhance productivity.

The second opportunity is pump selection – electric or air driven. With or without flow enhancers like liquid flow eductors, if air operated, the use of microprocessor stroke optimized controls on AODD pumps should be considered.

If only agitation is required, it is usually to keep solids in suspension, and then there are a range of options to replace or reduce compressed air usage including such mechanical devices as propellers, paddles, etc.

As you look at your industrial wastewater system, let your imagination be your guide. As they say, “think outside the box”.

For more information visit APenergy at https://apenergy.com.

To read similar articles on Industrial Wastewater please visit

https://www.blowervacuumbestpractices.com/industries/wastewater.

Visit our Webinar Archives to listen to expert presentations on Aeration Blower Systems at https://www.blowervacuumbestpractices.com/magazine/webinars.