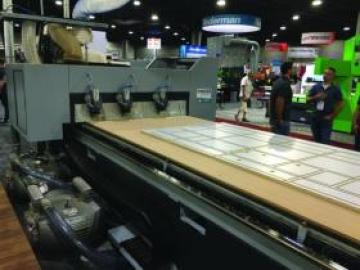

Versatile Vacuum Technology is a Force Behind Industrial Woodworking

There’s a lot of vacuum going on in the woodworking industry. From treatment to routing to handling, vacuum systems help meet the demands for higher speed performance, greater precision, faster production and better quality. Vacuum technology enhances the skills and talents of operators. Woodworking facilities of all sizes and production capabilities can precisely target their vacuum requirements to deliver maximum output. Here’s an overview of the most significant woodworking vacuum applications.