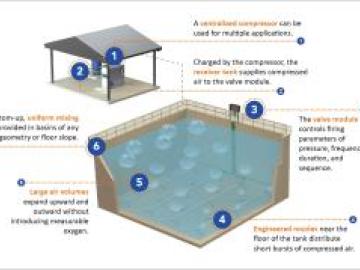

Aerzen Delta Hybrid Blower - Designed for Wastewater Treatment Plant Load Profiles.

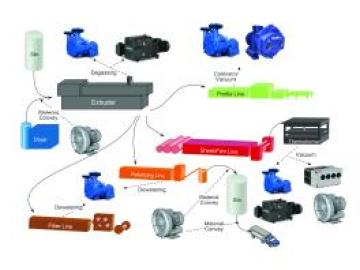

The concept offers new possibilities for generating positive pressure or vacuum in a variety of applications. “By applying screw compressor technology to low-pressure air compression, we’ve greatly improved efficiency,” said Pierre Noack, President and CEO of Aerzen USA. The Delta Hybrid has seven patents or patent applications, making it one of the most innovative products in compression technology.