When selecting the right oil for Positive Displacement (PD) blowers or vacuum boosters, it’s important to consider the three primary components the oil is formulated to protect: bearings, seals and gears. Oftentimes, the best option for one of these is not the same as the best option for the others, so a choice needs to be made for the most critical component, while also accounting for the secondary ones.

Failure to use the correctly specified oil for bearings, seals and gears often results in reduced performance, higher operating temperatures, unexpected maintenance, and catastrophic failure. All of these affect the bottom dollar and production. Also important to remember is that while ambient air temperature has some effect on the overall temperature of the blower, the unit’s gears, seals, and bearings are first and foremost concerned with what is occurring inside of the oil sumps, not outside.

The oil temperature, speed, shaft diameter, gear size, and bearing type are of primary importance, and overlooking these parameters in specifying the proper oil is an oversimplification that may result in machine damage and a foreshortened operating life. Here’s a review of these critical components and what to know to help specify oil for these components to help ensure peak performance and machine longevity.

Seals without proper lubrication can blister as shown.

The Vital Role of Bearings, Seals and Gears

Let’s first discuss bearings. The differential pressure, rotor weight, belt tension, and helical gear loads are all fully supported by the bearings. They have a big job to perform and must perform at full speed for months or years without failing. Additionally, roller and ball type bearings are often a considerable source of wear due to the metals and heat. Correct oil specification is critical for protecting these key components from metal-to-metal contact, high temperatures, sludge build-up, corrosion, and chemical outbreak. When specifying the oil formulation for bearings it’s important to balancing various factors such as bearing type, speed, size, and loading characteristics.

Seals, meanwhile, ;perform a crucial function in providing a barrier between the oil in the sumps and the process gas and ambient air. Unlike bearings, which experience mostly rolling friction, lip and mechanical face seals endure perpetual sliding and the resistance and heat generation that accompany it. It is critical that the specified oil is properly suited to provide the adequate film strength and cooling capacity under load and at the necessary operating temperature and speed. Improperly lubricated seals blister, crack, and can even leak.

Perhaps the most critical components considered when determining the proper oil for a positive displacement rotary lobe blower are the gears. Some manufacturers use hardened, matched helical gearsets for higher load capacity, longer life, ease of timing adjustment, and quieter operation. This style of gear requires special consideration because of the relative sliding that occurs between meshing teeth. The oil must be equipped to handle the accelerated thermal breakdown occurring in localized hot spots which are created by the immense pressure at the points of contact. Viscosity must remain sufficient at the operating temperature in order to maintain a proper film thickness between sliding faces. Improper gear lubrication leads to abrasive and fatigue wear, loss of timing, increased wear metals, and catastrophic failure.

Factors Impacting Oil Temperatures

While blower speed, shaft diameter, gear size, and bearing type are all known with certainty after sizing a blower or booster for an application, bulk oil temperature tends to be a bit more elusive. In an existing installation, this can be measured relatively easily but it may be difficult to predict for new applications. Several factors play a role in pushing the bulk oil temperature one direction or another:

- Inlet and discharge temperatures.

- Cooling methodology.

- Ambient conditions.

- Blower speed.

- Geometry and mass.

The dominant drivers of oil temperature in positive displacement blowers are inlet and discharge gas temperature. With regards to the inlet, a cooler incoming gas produces a notable convective cooling effect. The compression of the process gas produces tremendous heat which is then transferred through the housing and end plates and into the oil sumps where it is absorbed. The discharge temperature is directly dependent on the amount of compression across the machine which is a function of shaft speed and the amount of restriction downstream. The combination of the two phenomena plays a large role in the bulk oil temperature at steady state.

Verifying Blower System Energy with PTC 13 – Webinar RecordingDownload the slides and watch the recording of the FREE webcast to learn:

|

The introduction of an external cooling source also drastically impacts the bulk oil temperature by its flow rate, temperature, and thermodynamic properties. This includes oil-cooling options for PD blowers and vacuum boosters, such as cooling coils used with splash submerged in the oil sumps or external heat exchangers.

Naturally, convective cooling occurs on the exterior of the machine at all times. Ambient temperature, relative humidity, and wind conditions all play a role in the amount of heat carried away via convective cooling. Colder air, higher relative humidity, and higher wind speed all work to cool the machine more effectively. Additional consideration must be given to the ambient temperature at startup.

Another factor influencing oil temperature is when blower speed varies while constant differential pressure remains constant. This is likely due to one of two trends. The first is a consequence of the convective cooling produced by the gas flowing through the inside of the machine. Faster, more turbulent flow removes heat more effectively than slower, more laminar flow. The second is simply a function of friction heating in the oil. The rate of the oil between rubbing surfaces like gear teeth or seal faces affects the amount of frictional heat generated in the oil, and consequently the oil temperature. A higher blower speed equates to more frictional heating. These two opposing trends compete with each other so the outcome may be unique for each model and application.

The last driver of oil temperature, and perhaps the most difficult one to predict, has to do with machine geometry, mass distribution, and thermal mass properties. The presence or absence of ribs or cooling features, surface roughness, machine shape, materials of construction, and overall bulkiness all contribute to or diminish heat transfer out of the pumping chamber and into the oil and ambient air.

Lubricant Delivery Systems

There are two common types of blower and vacuum booster lubrication systems: splash lubrication and integral, or forced, lubrication methods.

Splash lubrication utilizes the gears and an oil slinger to distribute oil by centrifuge to all critical locations inside the machine. If the blower speed is varied, the amount of oil delivered to the critical components will also vary proportionally. Submerged oil cooling coils are an important option available with splash lubricated models in high-temperature applications.

Integral lubrication systems distribute the oil to key locations using an onboard positive displacement pump and an oil line distribution network. It also features an oil filter and heat exchanger (shell-and-tube type or cooling coils). For larger blowers and vacuum boosters, the oil sump volume is substantial and distributing adequate lubricant to all of the critical components using splash lubrication becomes challenging, especially in applications where the machine speed is varied to match the changing demand conditions. Forced lubrication allows for greater accuracy in delivering lubricant to critical components such as bearings, gears, and seals, even at varying speeds. For this reason, integral lubrication is recommended for large blowers and vacuum boosters, especially above the five-inch gear size.

Blower & Vacuum Technology Monthly e-NewsletterEnergy Conservation Measures are identified in aeration blower, industrial blower and industrial vacuum systems with case studies and technical articles from leading engineering firms, consultants and equipment OEMs. |

Factors Influencing Useful Oil Life

All oils eventually wear out and lose their effectiveness over time. The rate at which this occurs can be influenced by many factors including application and operating conditions.

Being comprised of a mixture of short and long hydrocarbon chains of varying purity and quality, mineral oils in API groups I through III will eventually break down. The tendency for these molecules to interact with oxygen and form more stable compounds is relatively high and the presence of oxygen, acids, water, or other catalysts increase this rate of degradation. The byproducts of this process are organic acids, varnish deposits, and sludge buildup on the components in the oil sumps.

All oils wear out, creating the potential for sludge buildup.

Similarly, heat plays a large role by increasing the rate at which chemical reactions can occur. This rate is governed by a generally accepted rule known as the Arrhenius equation, named for the Swedish chemist Svante Arrhenius. This formula demonstrates the temperature dependence of chemical reaction rates. For mineral oils, the general rule states the useful life of the oil halves for every 18 degrees above 160°F.

One indication of oxidative breakdown is a change in the Total Acid Number, or TAN. TAN represents the number of milligrams of potassium hydroxide (KOH) needed to fully neutralize one gram of oil to a pH of 7.0. Since no blower experiences ideal conditions, monitoring changes in the oil’s TAN can be helpful for determining the end of the oil’s useful life due to oxidation. It is important to emphasize that new oils may begin their life with a TAN above zero and that the change in the TAN is important to track. Significant changes in TAN indicates a substantial chemical change or contamination has occurred, and the base oil and additive package have been broken down to an ineffective level.

Contamination of any kind can prompt a notable change in the tribological, chemical, and thermodynamic properties of any oil. For example, dissolved water content of just 0.1% (1,000 ppm) can reduce the bearing life by up to 80%. In some cases, the presence of water can accelerate the oxidation rate of the oil by up to 10 times, resulting in acid generation, corrosion, and additive mortality. If the water content increases beyond the temperature dependent saturation level, additional water can no longer be dissolved and will become emulsified, or suspended, in the oil. A cloudy appearance and a significant viscosity change are the results of emulsified oil.

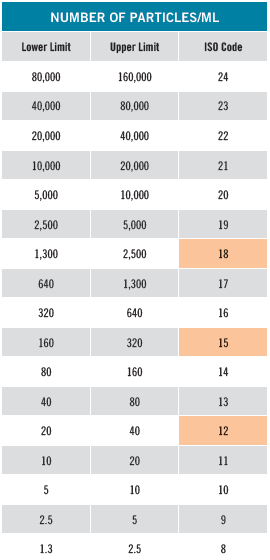

Other contamination, such as that from the processed gasses or from wear metals, can also pose a significant threat to the critical components of the machine. If this type of contamination is unavoidable and significant, a magnetic drain plug and an onboard or stand-alone oil filtration system should be considered. The International Organization for Standardization (ISO) provides guidelines for fluid cleanliness in ISO 4406:99 by setting targets for the maximum number of particles per mL in the size ranges of 4 μm or larger, 6 μm or larger, and 14 μm or larger. (See Table 1.)

Table 1: ISO cleanliness codes.

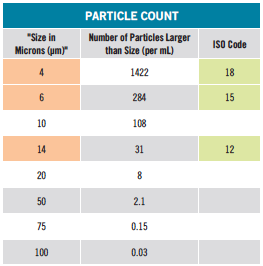

The target fluid cleanliness rating for oil used to lubricate gears is 17/15/12. This means it should contain fewer than or equal to 1,300 particles per mL (code 17) larger than 4 μm, fewer than or equal to 320 particles per mL (code 15) larger than 6 μm, and fewer than or equal to 40 particles per mL (code 12) larger than 14 μm. Table 2 shows an example particle count for a used oil sample with an ISO rating of 18/15/12.

Table 2: Sample particle count.

Oil Sampling Program Recommended

Given the uniqueness of each real-life scenario, it is impossible to accurately predict oil life without firsthand application experience. The oil may become contaminated or wet long before it has reached an unacceptable level of oxidation. It may become diluted with condensable process fumes and lose its viscosity long before it becomes contaminated with particulates or wear metals. Therefore, a regular oil monitoring or sampling program is always recommended to stay ahead of changes in the oil’s condition so problems can be addressed before they lead to catastrophic failure and expensive downtime.

About the Author

Brendan Pankratz is an Application Engineer with the Applications Engineering Group at MD-Kinney Vacuum & Blower Systems.

About MD-Kinney

The M-D Pneumatics and Kinney brands have a 100+ year history of providing long-lasting quality products and reliability to the industrial markets, but our most valuable assets reside in our knowledgeable co-workers and MD-Kinney representatives who manufacture, service, and build strong relationships with our customers. For more information, on MD-Kinney brands visit us online to learn more about our history and who we are.

All photos courtesy of MD-Kinney.

To read similar articles about Industrial Blowers, please visit https://www.blowervacuumbestpractices.com/technology/industrial-blowers.