Introduction

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are becoming more common in warehouse logistics and material handling industries. With the growth of e-commerce spurred by the pandemic, the need to further automate warehouse operations becomes even more apparent.

AMRs and AGVs can automate receiving and unloading, picking, stacking, storing and even inventory management. They can also move autonomously without causing harm to people working in the same area. And especially when paired with vacuum lifting systems, these vehicles can completely streamline material handling processes.

Overcoming Challenges

However, there are challenges to powering these vehicles and their attachments. Because they are smaller and lighter, the size of components and the power they need to operate matters. Most AMRs and AGVs are battery operated, so it’s important to balance the need for high efficiency with also providing high levels of torque.

Enter the GCPi, a new electrical compact pump from Schmalz. This vacuum generator was designed to provide maximum performance with minimum energy consumption. Older versions of similar vacuum pumps were too big and heavy to work for AMRs and AGVs, so Schmalz set out to create an innovative new take on vacuum generation.

Weighing in at just 3 kilograms, the GCPi in combination with a battery (only needing a 24-volt supply) is ready for mobile applications and is significantly cheaper to operate than a comparable ejector.

Here are five ways that the GCPi is uniquely positioned to provide vacuum solutions for a mobile format:

Purely Electrical

The GCPi was developed for compressed air free production and assembly and the 24V technology allows for complete mobile use.

High Speed

With a 46 l/min suction rate, this compact vacuum pump doesn’t hold back when it comes to speed. And the quick ventilation function also allows for fast depositing.

Highly Energy Efficient

The GCPi is characterized by its outstanding energy efficiency, which is important for not draining the battery of AMRs and AGVs. The electric 3/2-way compact valve LQE is what provides a compressed air free vacuum system that performs at the same level as conventional pneumatic systems.

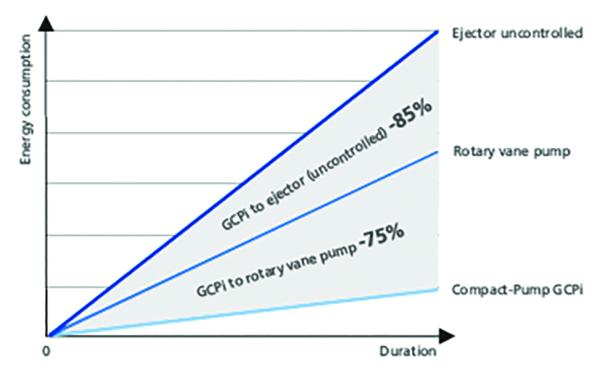

The FQE venting valve reduces the volume to be evacuated by preloading and enables rapid aeration. The diaphragm pump technology and intelligent vacuum control also support this efficiency. In certain applications it has been proven to be up to 75% more efficient than a classic rotary vane pump and up to 85% more efficient than an uncontrolled ejector.

Energy savings potential.

Process Control

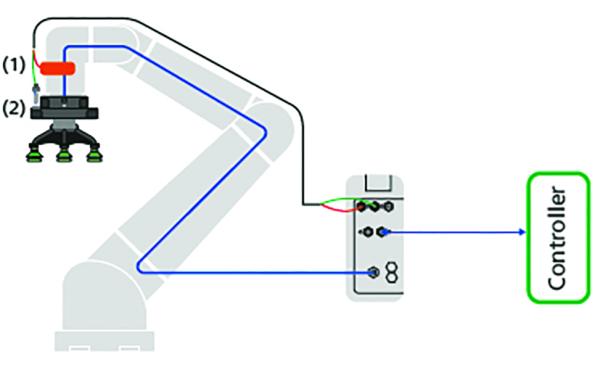

The compact pump GCPi can control up to two outputs with the X11 and X12 ports. This allows the option to connect either one actuator and one sensor or to use the GCPi to control two sensors and two actuators.

Control of external components.

IoT ready

The GCPi has full connectivity through IO-Link and can set the parameters by scanning the NFC tac with the Schmalz ControlRoom app. This technology allows the device to transmit data about its status, energy consumption and vacuum process directly at the gripper for condition and energy monitoring.

About Schmalz

Schmalz is the global market leader in vacuum industrial automation and ergonomic material handling solutions. The wide range of products in the Vacuum Automation unit includes individual components such as suction cups and vacuum generators, as well as complete robotic gripping systems and clamping solutions for holding workpieces, for example in CNC machining centers. The Handling Systems unit offers innovative handling solutions with vacuum lifters, servo hoists and workstation crane systems for industrial material handling applications. The intelligent energy saving solutions make production and logistics processes more flexible, productive and efficient, while also preparing them for the increasing trend toward digitalization. For more information, visit our website at schmalz.com.

For similar articles on Industrial Vacuum System Assessments, visit https://www.blowervacuumbestpractices.com/system-assessments/vacuum-systems.

Visit our Webinar Archives to listen to expert presentations on Industrial Vacuum Technology at https://www.blowervacuumbestpractices.com/magazine/webinars.