The beginning of September 2017 marked a milestone in the history of nanotechnology research: With the inauguration of the European XFEL (X-Ray Free-Electron Laser), the world´s largest and most powerful X-ray laser was officially put into operation. It will completely open new areas of research and insights into the nanocosmos that were never achieved before.

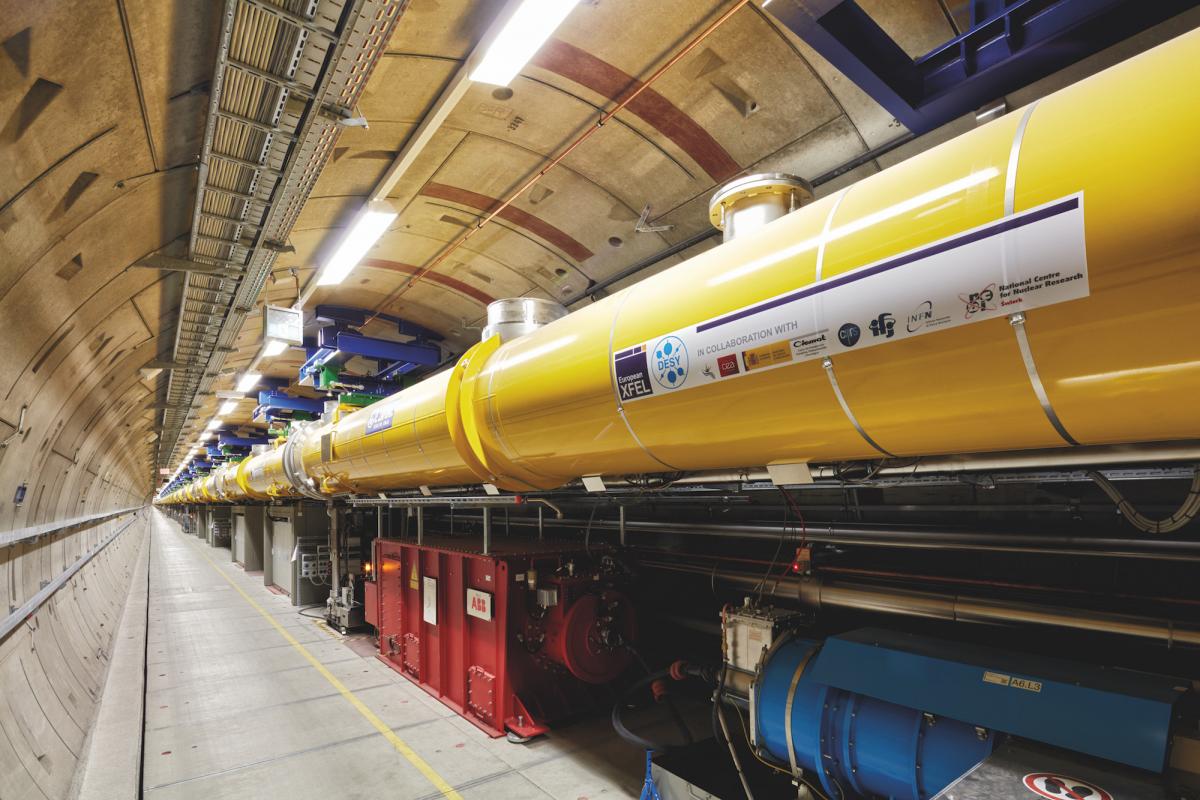

View from inside the XFEL accelerator tunnel (© European XFEL / Heiner Müller-Elsner)

The European XFEL is a new international research facility, where 12 European countries participate. The non-profit society European XFEL GmbH is responsible for the construction and operation of the X-ray laser. DESY (Deutsches Elektronen-Synchrotron), one of the leading centers for the investigation of the structure of matter worldwide and a long-term partner of Pfeiffer Vacuum, is the main share- holder. The facility starts at the DESY site in Hamburg and stretches to the town of Schenefeld in the German federal state of Schleswig-Holstein.

The interdisciplinary research at the European XFEL will deliver valuable insights into many areas of science. Experience from this type of basic research shows important applications develop. Many areas of science will profit from the new facility such as medicine, pharmacology, chemistry, physics, materials science, nanotechnology, energy technology, and electronics.

Using the unparalleled X-ray flashes of the European XFEL, scientists can decipher the atomic details of viruses and cells, take three dimensional images of the nanoworld, film chemical reactions and study processes such as those occurring deep inside planets.

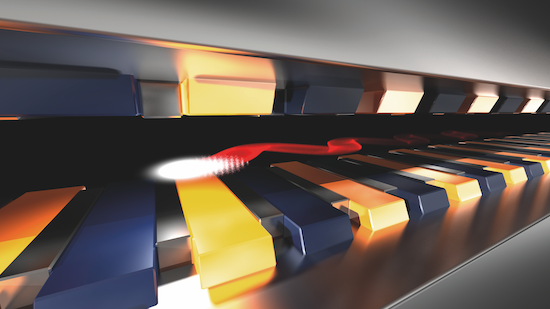

To generate the X-ray flashes, bunches of electrons are first accelerated to high energies, and then directed through special arrangements of magnets called undulators. Undulators are arrays of permanent magnets placed in an alternating pattern. They force accelerated electrons onto a zigzag slalom course. With every turn, the electrons emit X-ray light. Due to the behavior of the X-rays in relation to the electrons, and the pattern of the magnets in the undulator, the light emerging is laserlike, with all of its waves in phase with each other. This means the European XFEL generates X-ray radiation with properties similar to those of laser light.

Generation of X-ray laser flashes in an undulator (© European XFEL)

All of these processes require ultra-high (UHV) or high vacuum (HV) conditions. Within several years of cooperation, Pfeiffer Vacuum developed matching vacuum solutions for the high vacuum applications inside European XFEL. All solutions were exclusively tailored to the specific needs and demands of these applications.

Interview with Ian Thorpe, Engineer for the High Energy Density (HED) Instrument at European XFELIan Thorpe, European XFEL’s instrument engineer for the High Energy Density (HED) instrument, explains where the vacuum solutions are used, the requirements they have to fulfill and why Pfeiffer Vacuum was chosen as a supplier. Pfeiffer Vacuum: Mr. Thorpe, could you please explain to us the most important characteristics of the X-ray laser? Thorpe: The European XFEL will open up areas of research that were previously inaccessible. Using the X-ray flashes of the European XFEL, scientists will be able to decipher the molecular composition of cells, record chemical reactions, study processes like those inside planets or map the atomic details of viruses. Pfeiffer Vacuum: For which processes do you apply vacuum technology during your work at European XFEL? Thorpe: I am an instrument engineer for the HED instrument at European XFEL. The HED instrument will focus on scientific applications of matter occurring inside exoplanets, of new extreme-pressure phases and solid-density plasmas as well as of structural phase transitions of complex solids in high magnetic fields. This is, for example, useful for research into planetary science, magnetism and plasma physics. We need a good level of vacuum to enable the XFEL beam and high power lasers to propagate and interact with matter without being affected by air molecules or generating spurious background signals, which will be picked up by the detectors. Pfeiffer Vacuum: Where do you use Pfeiffer Vacuum solutions? Thorpe: At the HED instrument, we have UHV X-ray optics and diagnostics in the optics hutch. These systems are pumped using ion getter pumps to maintain the UHV conditions. As the beam line passes into the experiment hutch, which is where the users of the instrument will conduct their experiments, the requirements for vacuum are reduced to high vacuum (HV). This is where the Pfeiffer Vacuum products come into use. Pfeiffer Vacuum: Are there further areas of application for the products from Pfeiffer Vacuum? Thorpe: Ultra-high and high vacuum applications at European XFEL predominantly use Pfeiffer Vacuum turbopumps, controllers and gauges. Moreover, also our portable pump carts are equipped with Pfeiffer Vacuum solutions. Pfeiffer Vacuum: Which of the characteristics of our solutions are especially important for European XFEL? Thorpe: First and foremost, it was crucial that they could be integrated into the specific XFEL control system. Moreover, their easy installation was a plus. Also, their low maintenance effort qualified them for our application.

HiPace turbopumps installed at European XFEL |

Pfeiffer Vacuum Supplied European XFEL with Comprehensive Vacuum Solutions.

At the HED instrument of European XFEL, multiple turbopumps from Pfeiffer Vacuum are used to increase the pressure from UHV to HV. This is where ion getter pumps cannot be used. The whole beam line is windowless, so the differential pumping stage not only has to cope with the different vacuum levels, it also has to be able to handle a sudden or unexpected influx of gas. Furthermore, the turbopumps have to maintain the UHV as a link on the side to the ion getter pumps, so as not to trigger the machine protection valves and shut off the beam.

Pfeiffer Vacuum also developed and supplied the customized flange for the large interaction chamber. The volume is approximately seven cubic meters. The solution from Pfeiffer Vacuum is specifically tailored to the needs of the application.

Interaction chamber at European XFEL equipped with Pfeiffer Vacuum solutions (© European XFEL)

By using 800-liter pumps on two specially designed manifold flanges, the customer’s demands were exceeded thanks to the higher compression. The pumping speed can now be tuned to the user requirements with more or less pumping speed, depending on the type of experiment. Moreover, user safety was guaranteed and the down time was minimized.

The vacuum experts from Pfeiffer Vacuum also recommended using more small pumps. If a large pump is to fail, this could not only be potentially dangerous, but also put the beam line out of operation until a replacement pump is fitted. Now, the pump can simply be replaced, or a blank flange can be mounted and the normal operation can continue until a convenient time to replace the pump is found.

In further high vacuum applications at the European XFEL, HiPace 80, 300 and 800 turbopumps and associated controllers are used. Moreover, gauges as well as flanges, viewports and standard parts are in operation. Additionally, Pfeiffer Vacuum designed and manufactured customized parts and instruments for the HED instrument. The HiPace turbopumps allow an easy integration into the XFEL control system. Pfeiffer Vacuum modified the pumps according to the XFEL standards by enabling the option to use deionized water for cooling. Pfeiffer Vacuum supplied customized cables matching the specific length of the XFEL standard connectors.

Vacuum Solutions from a Single Source

Special vacuum components, such as flanges and pipe components, were developed for the use in European XFEL´s electron beam lines. The used turbopumps and mass spectrometers were designed in close cooperation with the customer to match the requirements. Special editions of leak detectors were also delivered according to the customer’s demands. Pfeiffer Vacuum successfully provided tailored vacuum solutions from a single source for the UHV and European XFEL.

Mr. Fabian Frey is the Market Manager R&D for Pfeiffer Vacuum. For more information contact Pfeiffer Vacuum. Tel: 800-248-8254, www.pfeiffer-vacuum.com.

To read similar articles on Medium and High Vacuum, please visit www.blowervacuumbestpractices.com/technology/medium-high-vac.