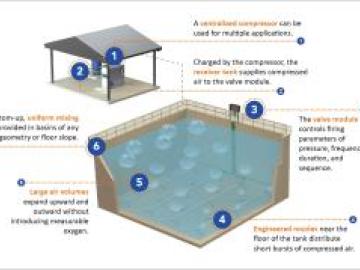

PTFE Membrane Bubble Diffusers Reduce Demand on Aeration Blowers

Aeration tanks use bubble diffusers to distribute oxygen within the wastewater. Fine bubble diffusers, or those that produce a large amount of very small air bubbles, first began to become popular in the 1980s, as they had a much higher efficiency than coarse bubble diffusers. Fine bubble diffusers generally feature a membrane that allows airflow to pass from the piping system on the floor of the tank through the body of the diffuser and the membrane, providing oxygen into the wastewater for treatment.